Clay 3D Printer

Open Source Delta style clay 3D printer

FabLab CEPT, Ahmedabad, India

2017 - Ongoing

All image courtesy : Radhika Thacker | Student Assitant, FabLab CEPT, CEPT University

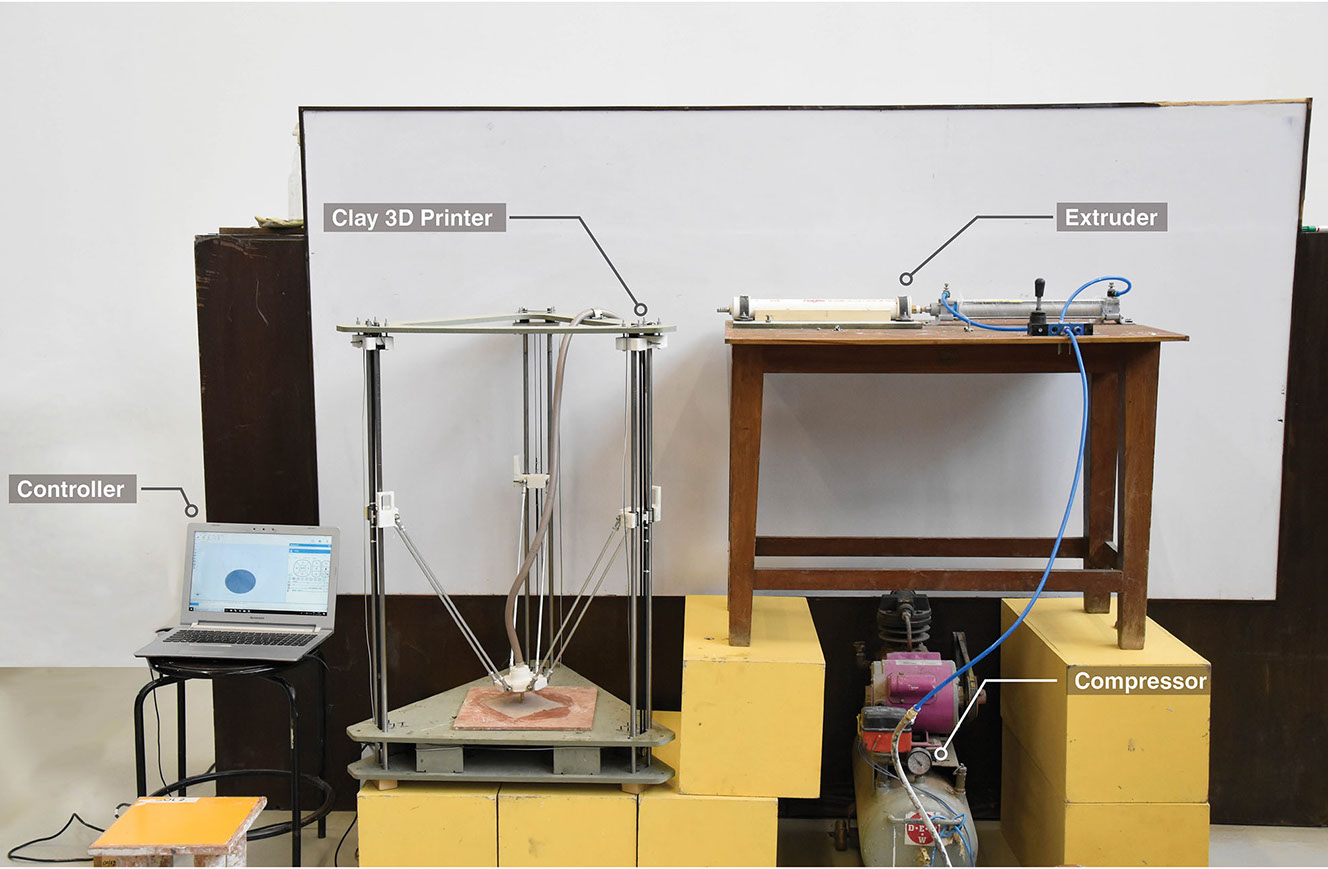

At CEPT University, we undertook a research of additive manufacturing architectural components using clay and concrete, led by workshop director Urvi Sheth. The first stage was to conduct an introductory workshop as part of Summer-Winter School taught by her and co-tutored by myself. We covered the basic tenets of clay/ concrete 3D printing focusing on tool, techniques and material.

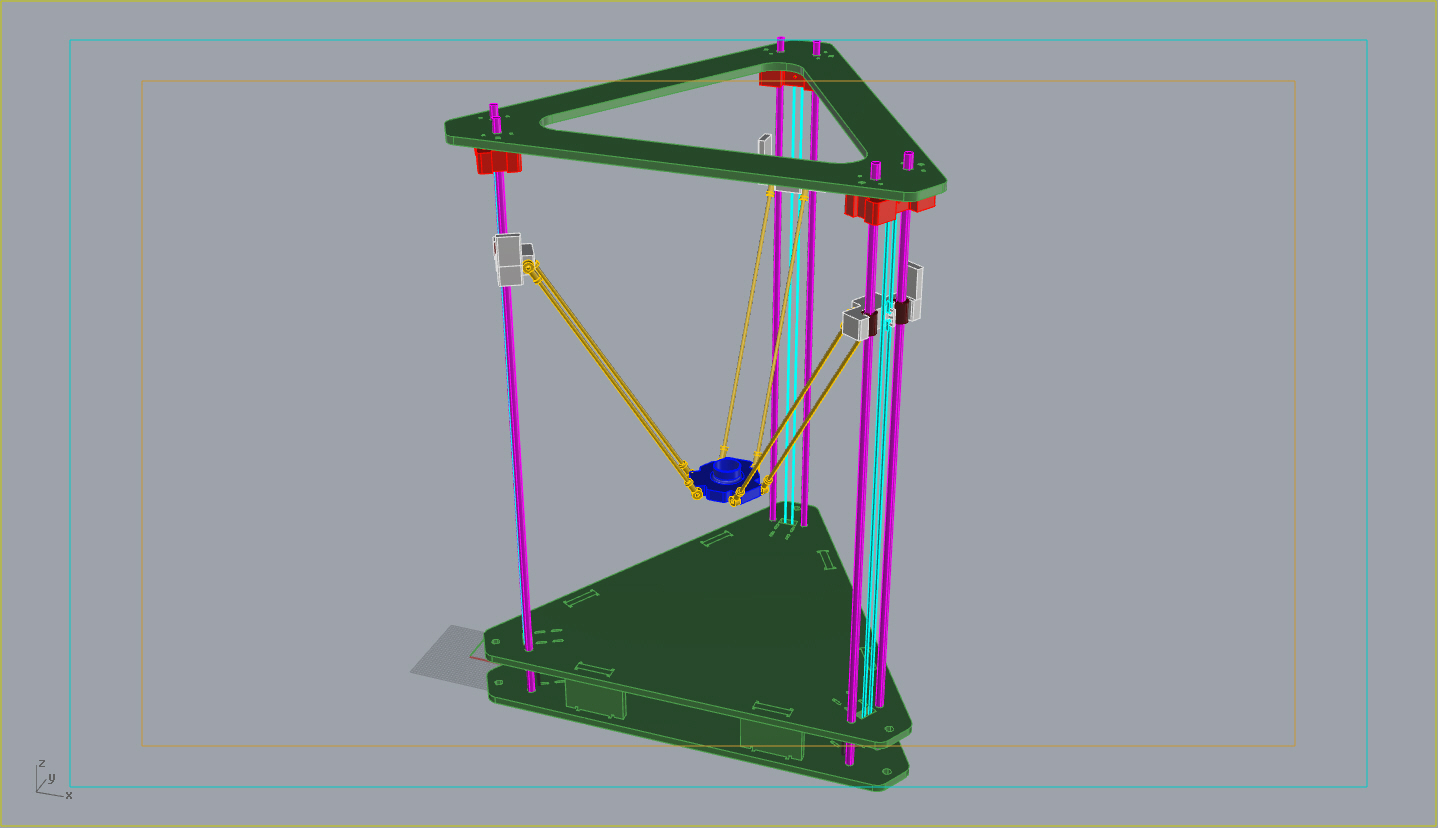

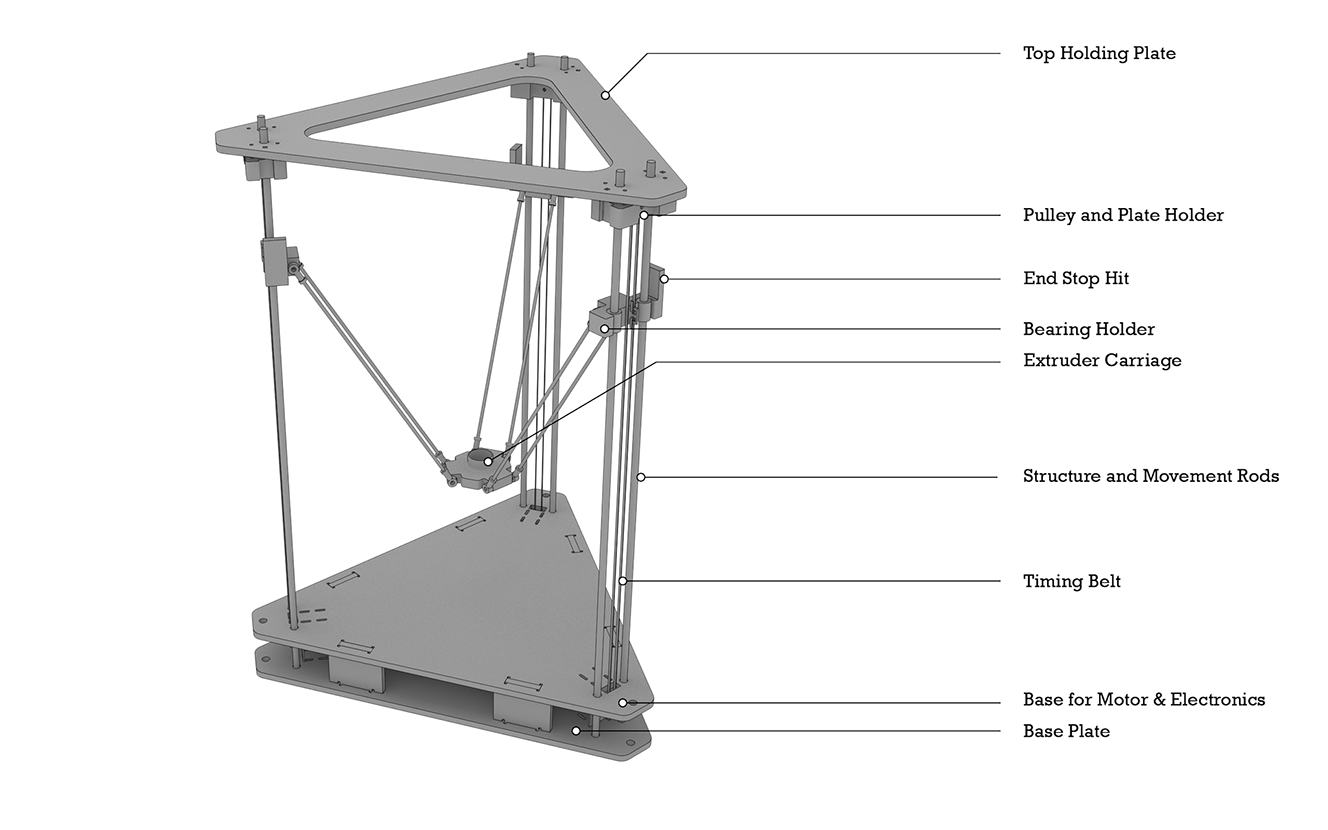

For the workshop, this 3D printer was built. The design was made in Rhino. Parts are CNC Milled, 3D printed and market bought. Marlin is used as the firmware and Repetier Host as the controlling software.

Credits:

Core Team | Design & Electronics: Avishek Das, Tanveer Khorajiya, Gaurav Wadhwa, Shrikanth KNR

Documentation: Radhika Thacker

Assembly: Radhika Thacker, Mehul Maiseri, Bhanga Vanu Teja, Shrikanth KNR with Avishek, Tanveer, Gaurav and Urvi Sheth, Workshop Director

Design of the Printer:

The design of the printer is hugely inspired from the works of artists Jonathan Keep and Olivier Van Herpt. Initially we started the design and making from a printer called Stratrum Networks by Max Sanchez and Taylor Fulton from Instructables. But those files we received was not accurate and we made a printer with a large amount of error.

Laser cut Printer Pieces

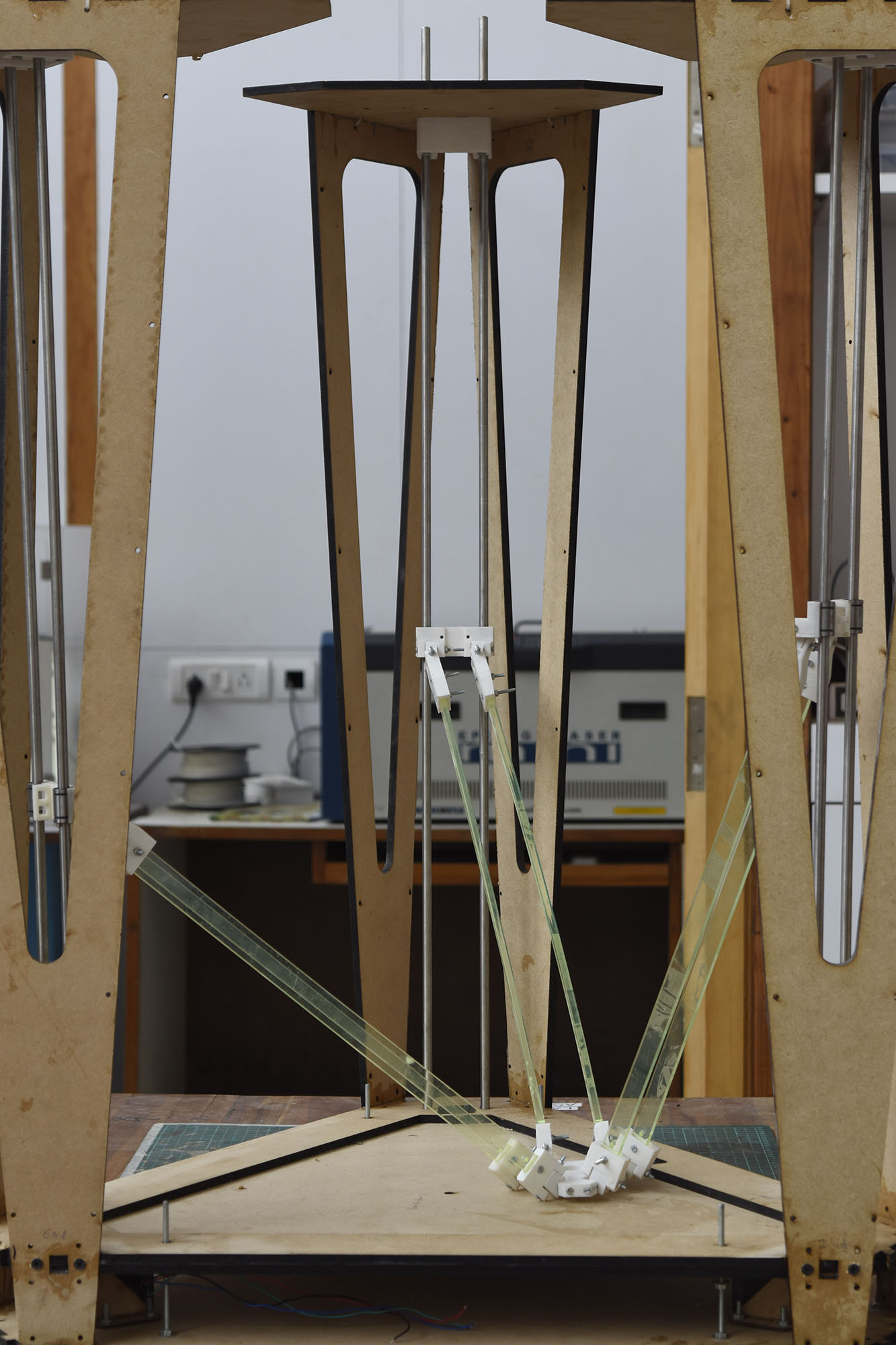

Assembled Printer

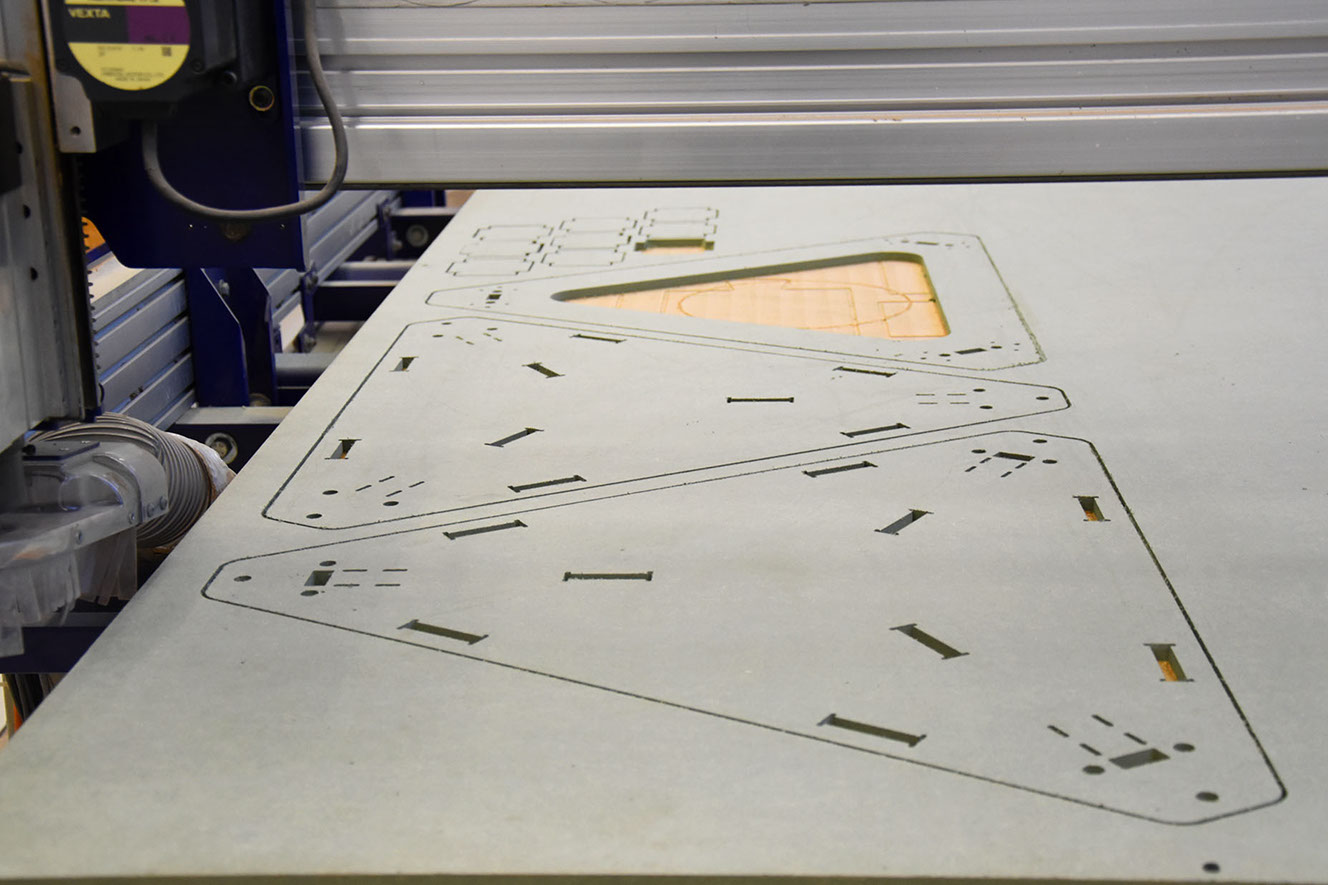

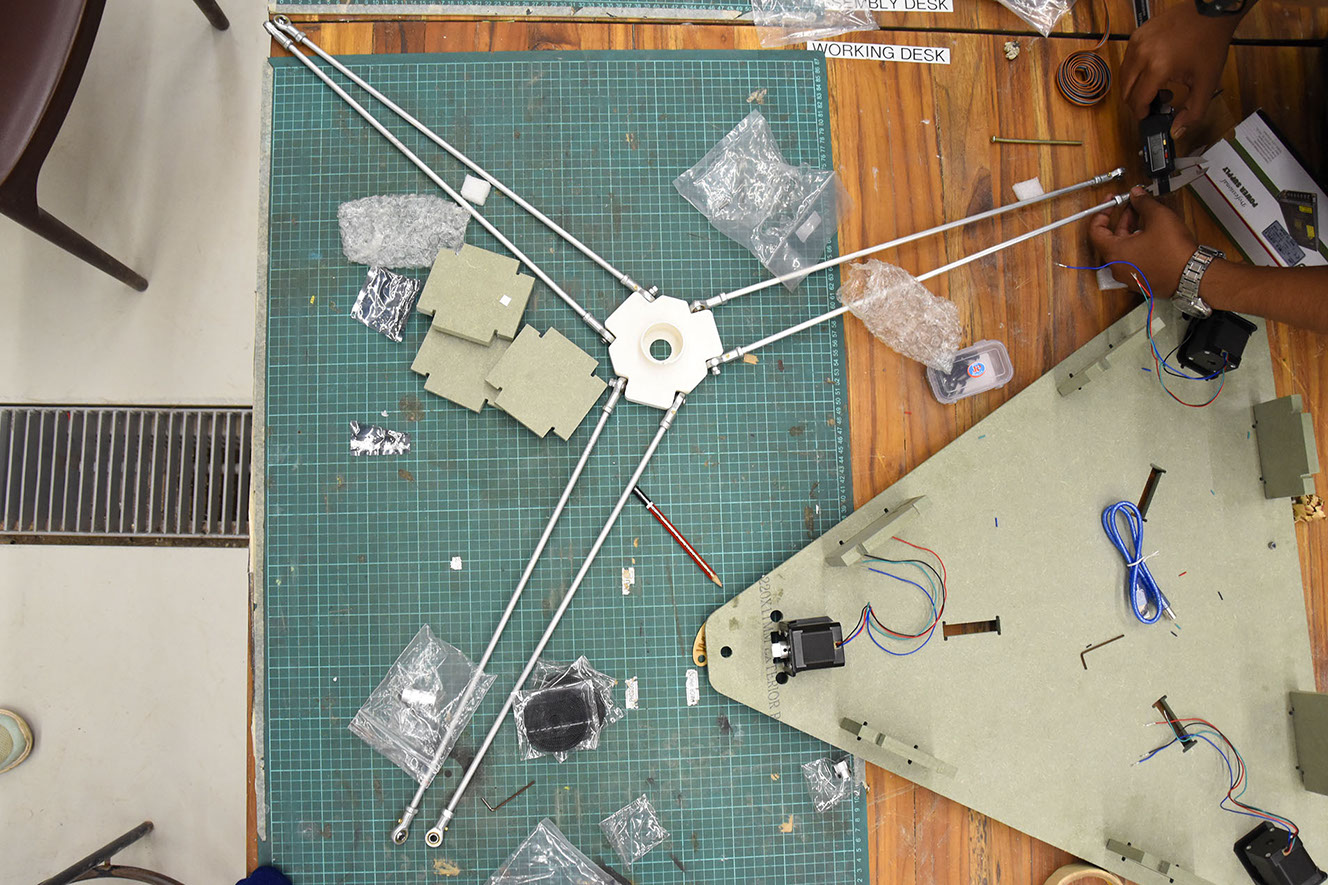

After noting down all possible upgrades and corrections we decided to move forward for a new machine. We decided to make the base out of CNC cut MDF and major parts with PLA 3D printed. At this stage we took inspiration from Olivier Van Herpt's printer for its simplicity.

At this stage, the main design was done by me; all 3D prints are overseen by Tanveer, Laser cut by Gaurav CNC by myself and Radhika.

3D model of the new printer.

CNC Cut pieces

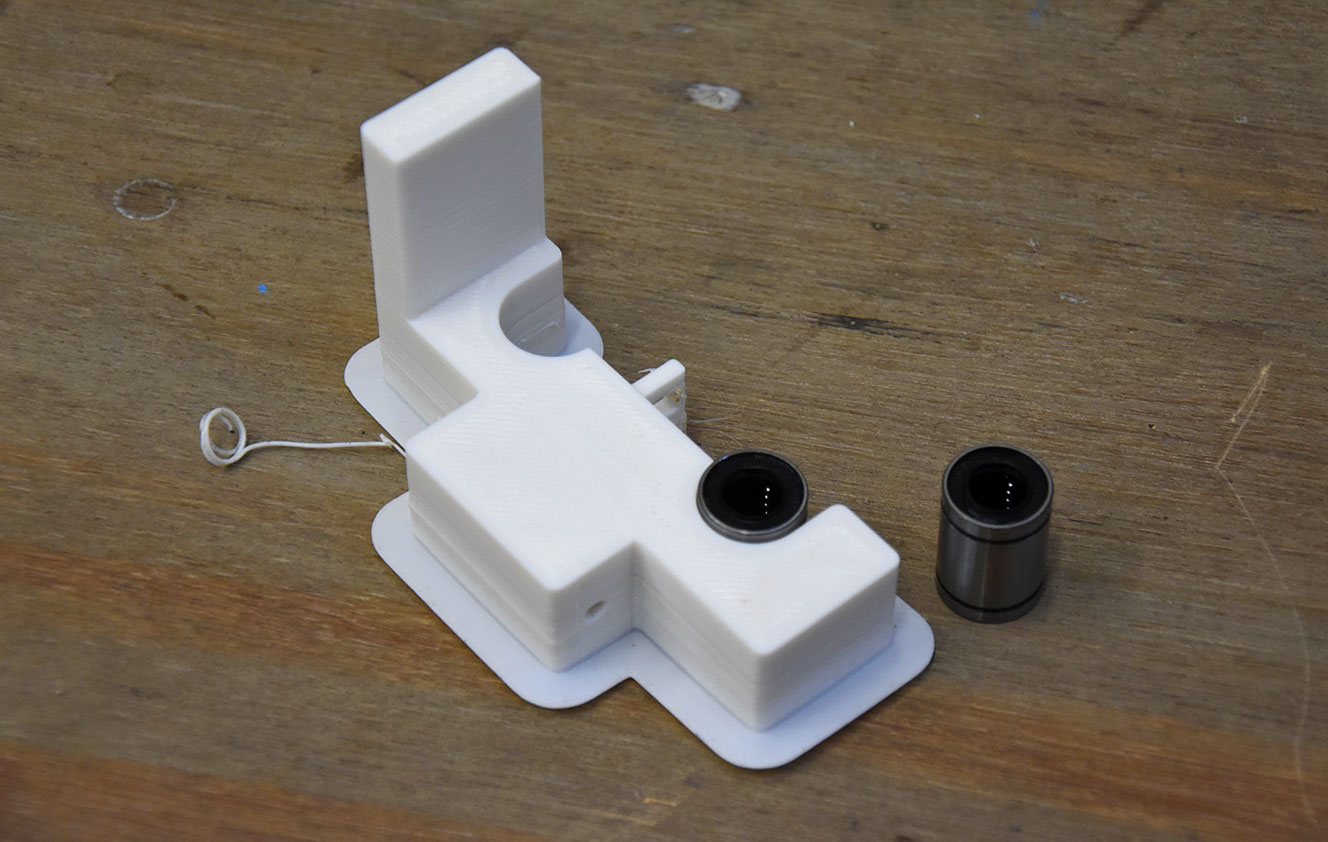

3D Printed pieces with bearings

3D Printed pieces with bearings + Ball Socket holder

On going assembly

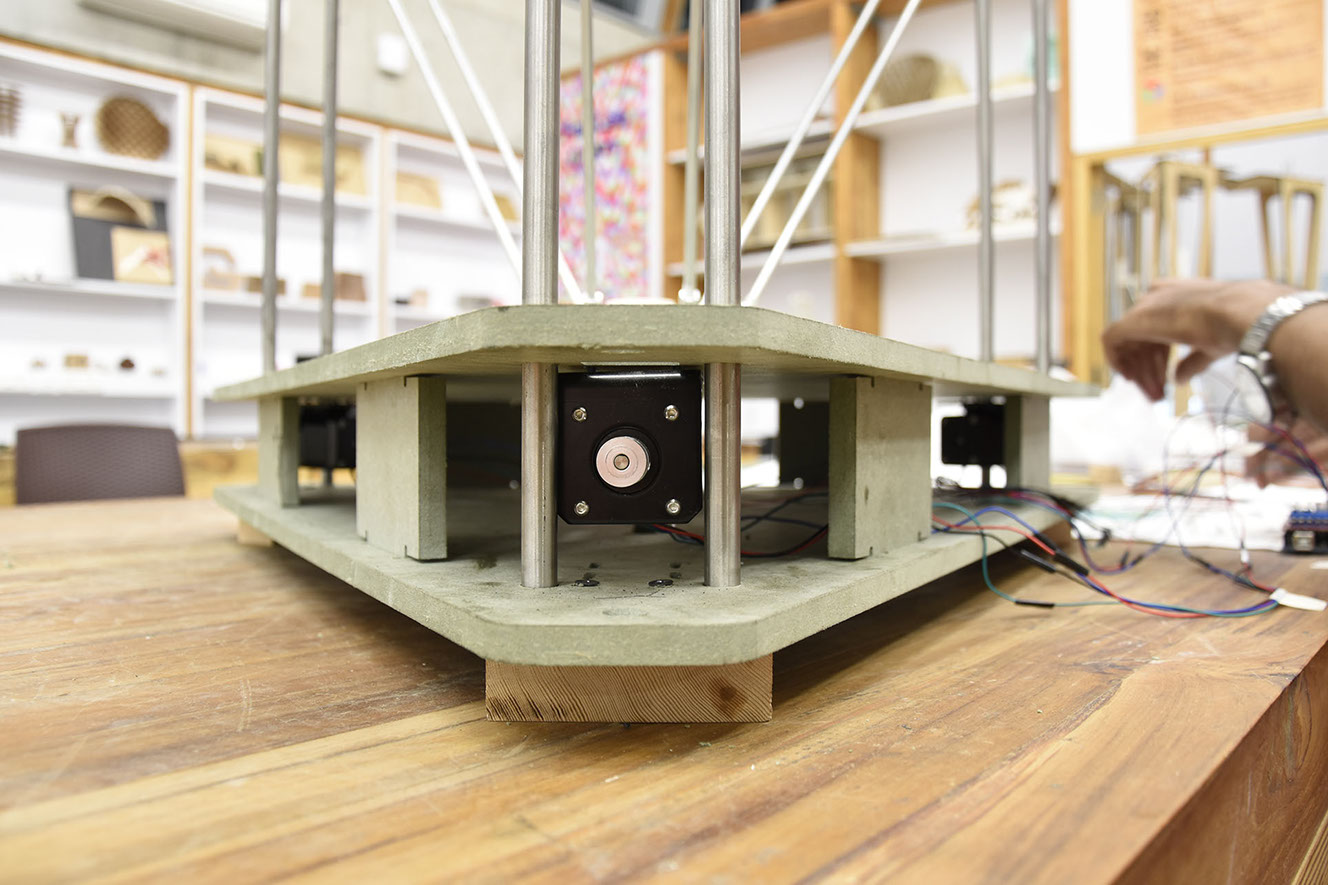

Motor assembly under the printbed

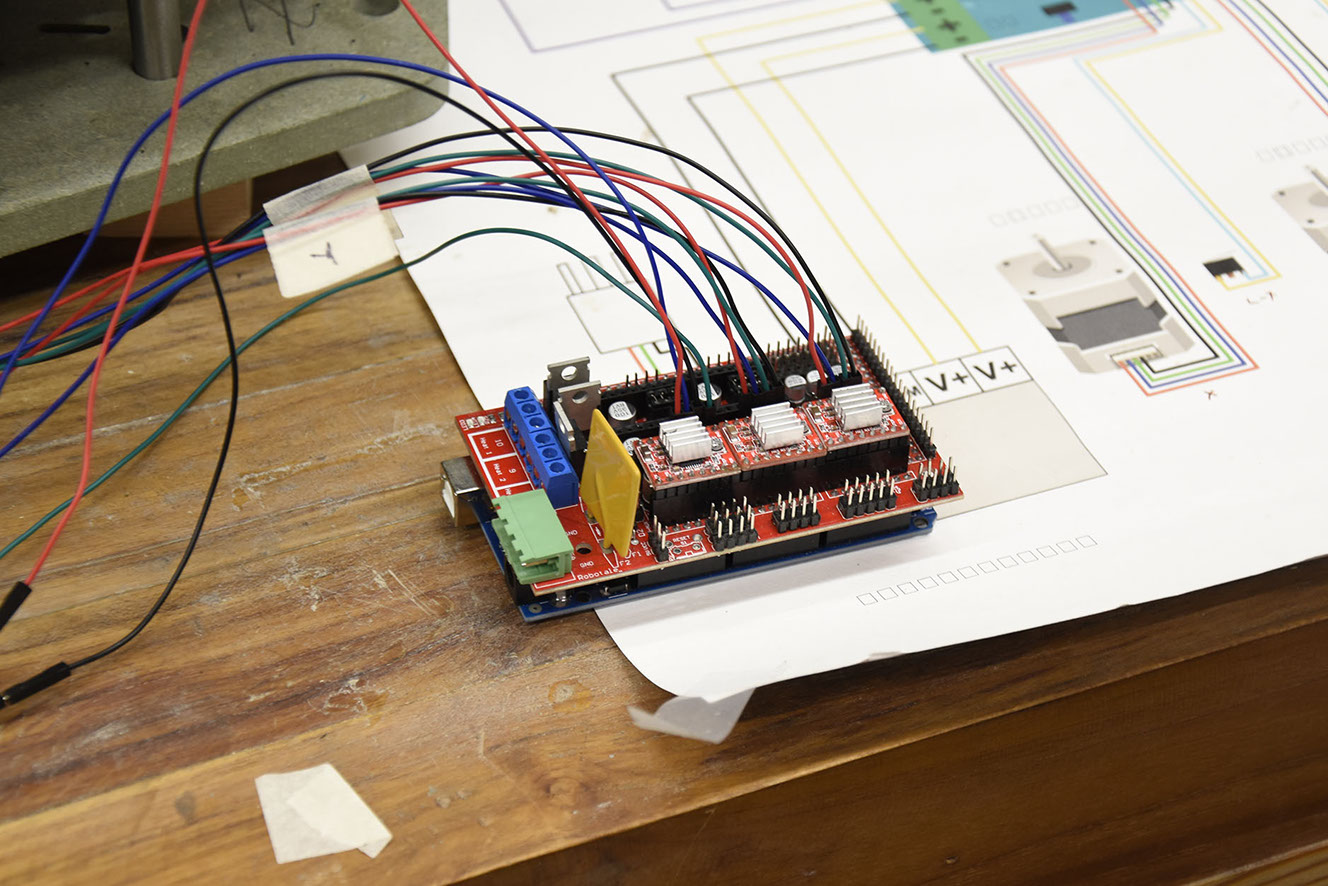

Electronics | Limit Swtich was added to it later

Finished Printer.Without extruder

Final Setup

top

avishek das | 2018